POSITION:首页 >> MATERIALS >> MolybdenumMolybdenum

With its unique mechanical and chemical properties, molybdenum is an outstanding material that can meet the most exacting requirements. Because molybdenum possesses a very high melting point,a low coefficient of thermal expansion and a high level of thermal conductivity, it is used in many different industries.

Molybdenum is a genuine all-rounder. We use this material, for example, to produce ribbons and wires for the lighting industry, semiconductor base plates for power electronics, glass melting electrodes, hot zones for high-temperature furnaces and sputtering targets for coating solar cells and flat screens.

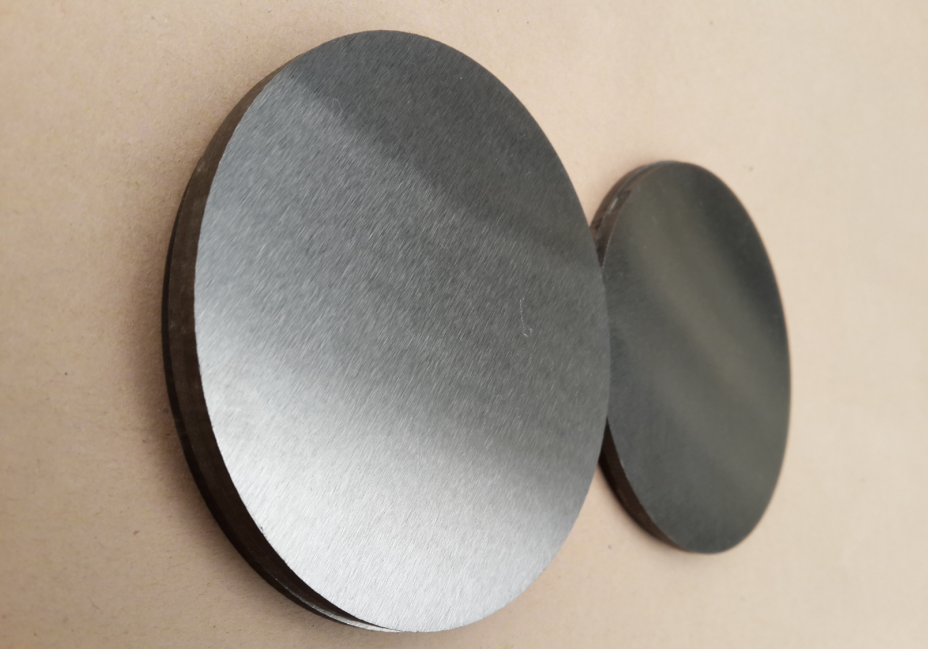

Mo(Pure Molybdenum)

The purity of Mo1 is greater than 99.95%.You can rely on our quality. We produce our molybdenum products ourselves – from the metal oxide right through to the finished product. As our input material, we use only the purest molybdenum oxide. This ensures that you benefit from a very high level of material purity.

TZM (Titanium-Zirconium-Molybdenum).

We transform our molybdenum into TZM by using small quantities of tiny, extremely fine carbides. TZM is stronger than pure molybdenum and possesses a higher recrystallization temperature and better creep resistance. TZM is used in high-temperature applications involving demanding mechanical loads, for example in forging tools or as rotating anodes in X-ray tubes. The recommended temperatures of use are between 700 and 1400℃.

MoLa (Molybdenum-Lanthanum Oxide).

MoLa (Molybdenum-Lanthanum Oxide).

Small quantities of lanthanum oxide particles (0.3 or 0.7 percent) give the molybdenum a so-called stacked fiber structure. This special microstructure is stable at up to 2000℃. Molybdenum-lanthanum oxide is therefore alsocreep-resistant even under extreme conditions of use. We mostly machine these alloys to produce furnace components such as stranded and other wires, sintering and annealing boats or evaporator coils. In the lighting industry, molybdenum-lanthanum oxide is used, for example, for retaining and feed wires.